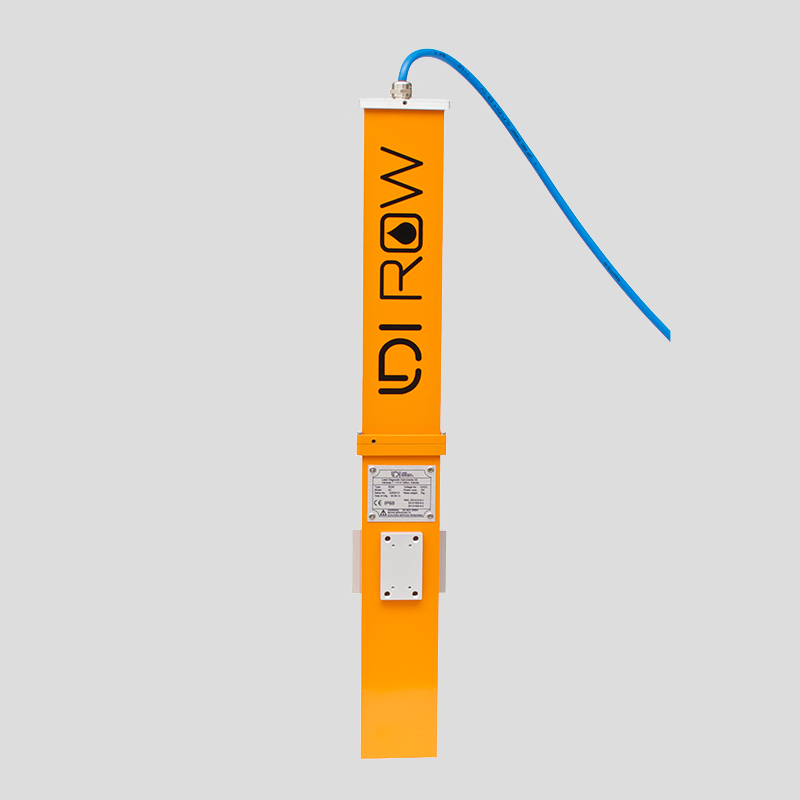

The ROW is a (oil on water) hydrocarbon detector. But the potential applications extend beyond oil facilities.

The ROW provides early warning against oil spills, so you can react quickly and effectively.

There are a diverse number of applications for the ROW oil on water detector. Major industrial facilities like power generation plants, manufacturing plants and even airports use or store hydrocarbons in one form or another. Accidental spills and leaks can happen at anytime. Then there are the waste water treatment plants or desalination plants who want to protect their facilities from external oil spills, whether its from tanker traffic or industrial oil spills.

Power Generation Plant, South Korea

Use Case

The hydroelectric turbine generators have lubricant oil filled bearings which, when not operating correctly or efficiently, release oil into an overflow pit inside the plant. The inability to detect this contaminated overflow leads to depreciated components lifespan, increased downtime and reduced plant productivity.

Solution

Using the ROW at K-Water's Imha and Daecheong installations provided critical continuous water monitoring of the plant's overflow pits, immediately alerting operators to any potential oil leaks. The ROW integrated seamlessly into K-Water’s systems allowing real-time monitoring and data analysis to the health of their generator turbines.

Oil Refinery, Belgium

Use Case

Accidental oil spills from process malfunctions and routine operations contaminate the groundwater and waterways. When oil spills do occur, they end up affecting the downstream water treatment facilities or worse, the local environment.

Solution

Installing the ROW ATEX enables the detection of a wide range of oils. Delivering alerts directly through existing systems or as a stand alone installation, the ROW ATEX is a flexible solution for real-time response to accidental oil spills.

Desalination and power generation plant, UAE

Use Case

This facility is located off the coast of a major Middle Eastern marine shipping lane in the UAE routinely populated by oil tankers. The desalination process requires clean water and detecting devastating oil spills before it reaches the plant's in-take is critical to normal operations.

Solution

The ROW is a low-power instrument (< 2W) meaning it can be mounted on an offshore buoy and connected with off-grid telemetry and solar power. The customer deployed 5 continuous monitoring ROWs on buoys surrounding their desalination plant, protecting it against incoming oil spills.

Water Treatment Plant, Chile

Use Case

Oil contamination into the local water can posed a serious problem to a treatment facility's normal operations: hydrocarbon can bio-foul the membrane filters, or destroy the bio-reactors, or clog the sand filter leading to potentially long plant shutdowns.

Solution

Installing the ROW at various upstream points leading to the water treatment plant provides 24/7 detection for such oil spills. This alerts operators to incoming contamination is diverted away from critical plant infrastructure and oil spill mitigation measures are put in place.

Shipping Port, Latvia

Use Case

Due to it proximity to a major capital, oil spills into the port area causes real environmental and social damage to the city of Riga. Whether from accident or nefarious cargo ship crews illegally discharging oily ballast water into the harbour, the port authority is responsible for the clean-up and government fines.

Solution

Installing multiple ROWs at various points around the port offers vital 24/7 monitoring of port waters, adding to the overall security apparatus of the port against any unsuspecting oil spills. The ROWs provides added-value against litigation as well as proper environmental solution to a tricky problem.