Is ROW Capable of Detecting Oil in All Weather Conditions and Harsh Environments?

Oil spills don’t wait for ideal conditions to happen. Whether caused by equipment failure, human error, or weather-related incidents, they can occur anytime—during storms, at night, in freezing cold, or under blazing sun. That’s why having an oil spill detection system that works reliably and consistently—regardless of weather or environment—is absolutely essential.

At Laser Diagnostic Instruments (LDI), this challenge has been central to product development for over 30 years. Their most advanced innovation, the Remote Optical Watcher (ROW), is designed to set a new standard in real-time, autonomous oil spill detection—even under the harshest environmental conditions.

Weather-Proof, Environment-Resistant Technology

ROW was engineered with one key principle in mind: reliability in all conditions.

From polar winters to tropical humidity, offshore oil rigs to industrial harbors, ROW maintains stable, high-performance monitoring thanks to several key features:

-

Rugged construction: ROW is available in both 316L stainless steel (marine-grade) and anodized aluminum housings. This ensures it can withstand corrosive environments such as saltwater exposure, industrial fumes, high UV, or chemical-laden atmospheres.

-

IP-rated enclosures: These make ROW resilient to heavy rain, snow, dust, and even sub-zero temperatures.

-

Built-in heater (optional): For installations in extremely cold climates, ROW can include a heater module to prevent fogging or ice buildup on optical components, ensuring uninterrupted operation.

Whether installed at a stormwater outlet, refinery basin, or remote coastal site, ROW operates unattended and uninterrupted—with no degradation in performance over time.

True 24/7 Detection — No Matter the Weather

Unlike other oil spill detection systems that may struggle in poor visibility, ROW uses laser-induced UV fluorescence to detect hydrocarbon presence on water surfaces. This method is not affected by darkness, fog, or water movement.

-

Operates day and night

-

Unaffected by cloud cover or poor visibility

-

Works even during heavy rainfall or snowfall

-

Can detect thin films of oil (as little as 1 micron)

ROW is a non-contact optical sensor—meaning it doesn’t need to be submerged or placed in direct contact with the water surface. This is a major advantage in rough sea conditions, rapidly changing water levels, or floating debris environments.

Advanced Detection Technology

At the heart of ROW is laser-induced fluorescence (LIF)—a technology that excites oil molecules using ultraviolet light, triggering a unique fluorescent signature. This allows the sensor to:

-

Differentiate hydrocarbons from other substances in water (reducing false alarms)

-

Detect a wide range of oil types (including light, heavy, and refined products)

-

Trigger alerts immediately when oil is detected, without waiting for sample analysis

This type of real-time oil spill detection is critical in sensitive environments like ports, airports, offshore rigs, and water treatment plants—where even a small spill can lead to massive environmental or financial damage.

Maintenance-Free, Energy-Efficient, and Autonomous

ROW isn’t just tough—it’s smart and low-maintenance:

-

Zero maintenance: No filters to clean, no moving parts, and no regular calibration required.

-

Refurbished parts: Consumables or damaged parts don’t need to be shipped back. The device can be refurbished on-site, reducing costs and downtime.

-

Low power consumption (<2W): Ideal for solar-powered or battery-supported systems in remote or off-grid locations.

-

Modbus RTU and 4–20mA: ROW integrates easily into existing SCADA or control systems for real-time alerting.

This makes ROW the ideal solution for long-term deployment in unattended or remote locations, reducing the need for technician visits and service interruptions.

Real-World Applications in Harsh Settings

ROW is already trusted by organizations across Europe, Asia, and Latin America in sectors where harsh conditions are the norm:

-

Airports (e.g., Charles de Gaulle, Guanacaste Intl.): monitor fuel spills from Jet A-1

-

Offshore oil platforms: detect leaks around loading arms and storage tanks

-

Military bases: safeguard water systems during fueling and vehicle operations

-

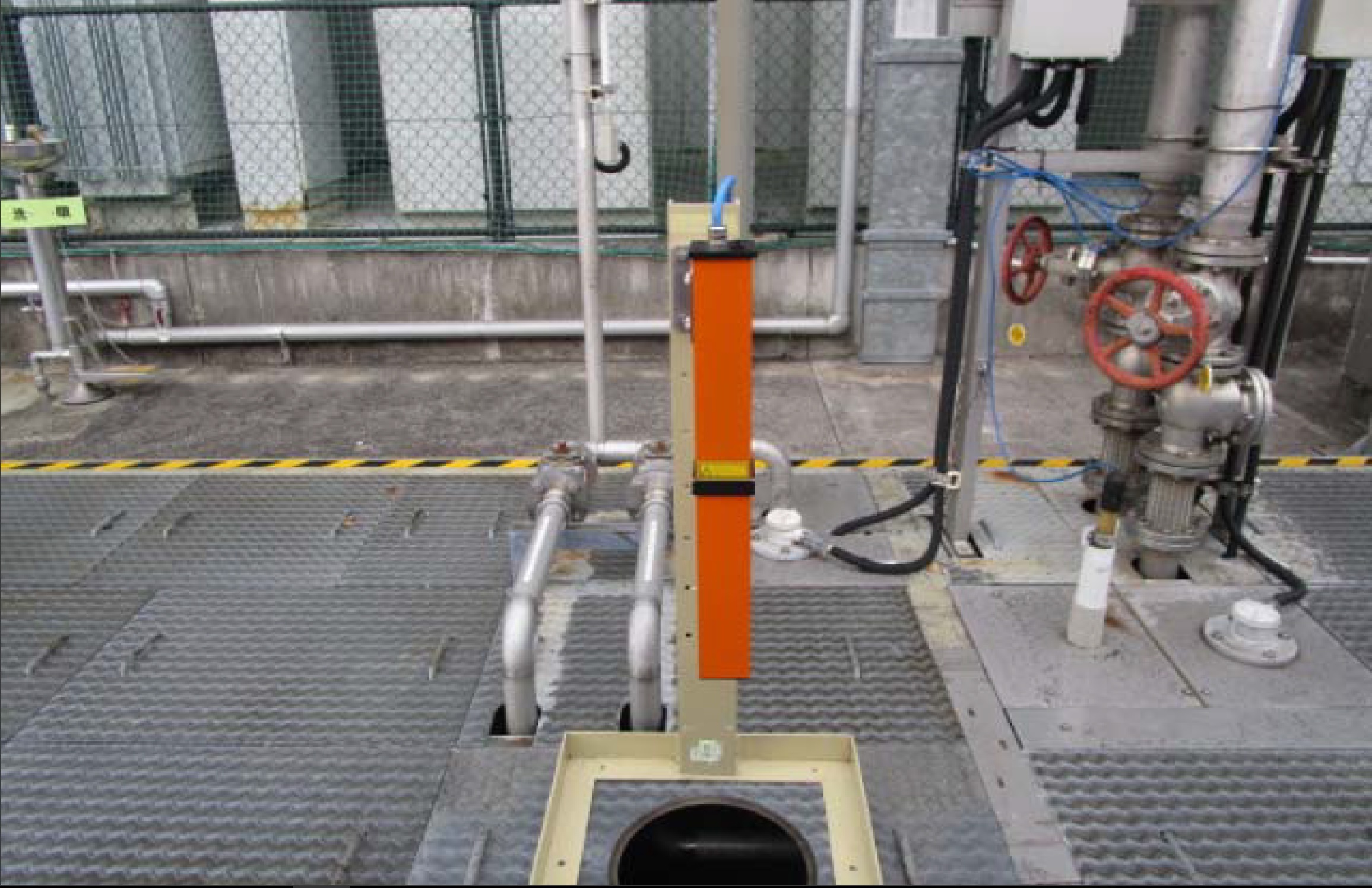

Power plants & wastewater sites: monitor stormwater discharge and basin overflows

In all of these environments, ROW provides peace of mind: accurate, real-time oil spill detection—no matter the temperature, humidity, or turbulence.

Key Benefits Recap

-

🔹 Refurbishable Design – Minimizes waste and promotes long-term sustainability.

-

🔹 Zero Maintenance – No recurring service contracts or parts replacements needed.

-

🔹 No Factory Returns – Easy to manage on-site, reducing downtime and logistics.

-

🔹 All-Weather Operation – Reliable detection even in snow, fog, rain, or night.

-

🔹 Non-Contact and Autonomous – Perfect for remote or hazardous locations.

-

🔹 False Alarm-Free – Industry-leading precision for trusted performance.

Want to learn more about how ROW can be integrated into your industry? Contact us today!

Search

Recent Posts

- Hydroelectric Safety Reinvented: Continuous Oil Monitoring for Turbine Protection

- Continuous Water Monitoring: Refineries and Oil Terminals

- Extreme Stress Test: How the LDI Sensor Survived a Ship Impact and a Month in the Frozen Sea

- LDI Demonstrates Autonomous Oil Spill Detection in Tallinn

- How ROW Supports the EU’s DIGIMARIS Marine Spill Response Project