Protecting Water Treatment Plants with ROW Technology

Water treatment plants—municipal, industrial, or desalination—play a critical role in preserving public health and environmental sustainability. These facilities face constant risk from hydrocarbon contamination, whether from industrial discharge, tanker spills, or upstream leaks. Continuous monitoring is essential to prevent damage, ensure compliance, and maintain operational efficiency. LDI’s Remote Optical Watcher (ROW) offers a robust, real-time, non-contact solution that protects both infrastructure and water quality.

Why Real-Time Oil Detection Is Crucial

Even minor oil contaminants can cause:

Damage to membranes and biological treatment systems

Clogging of filters and reduced processing efficiency

Regulatory violations and costly cleanups

Risks to public safety and environmental health

Early detection enables rapid intervention, reducing risks and preserving water system functionality.

ROW’s Advanced Oil Detection Capabilities

1. Non-Contact UV Fluorescence

ROW uses pulsed UV LEDs to detect ultra-thin oil films (≤ 1 µm) from up to 10 m above water. Its IP68-rated housing ensures durability and accuracy without requiring water contact—ideal for water treatment environments.

2. 24/7 Monitoring with Instant Alerts

Installed at intake, discharge, or retention points, ROW provides round-the-clock surveillance and real-time notifications via relay, 4–20 mA, or Modbus—integrating easily with SCADA or LMS systems .

3. Low-Power Operation

With power consumption below 2 W and solar/battery compatibility, ROW is optimal for off-grid or remote installations.

4. Rugged, Maintenance-Free Design

Available in aluminium, 316L stainless steel, and ATEX-rated enclosures, ROW withstands rugged conditions and features LEDs with a 5‑year lifespan, minimizing maintenance needs and eliminating factory returns .

Real-World Installations

La Mochita Municipal Plant, Chile

ROW was deployed to protect treatment infrastructure from hydrocarbon intrusion. The system’s ability to detect even minute spills helped prevent filtration damage and reduced downtime in the local water treatment process

Abu Dhabi Desalination Plant

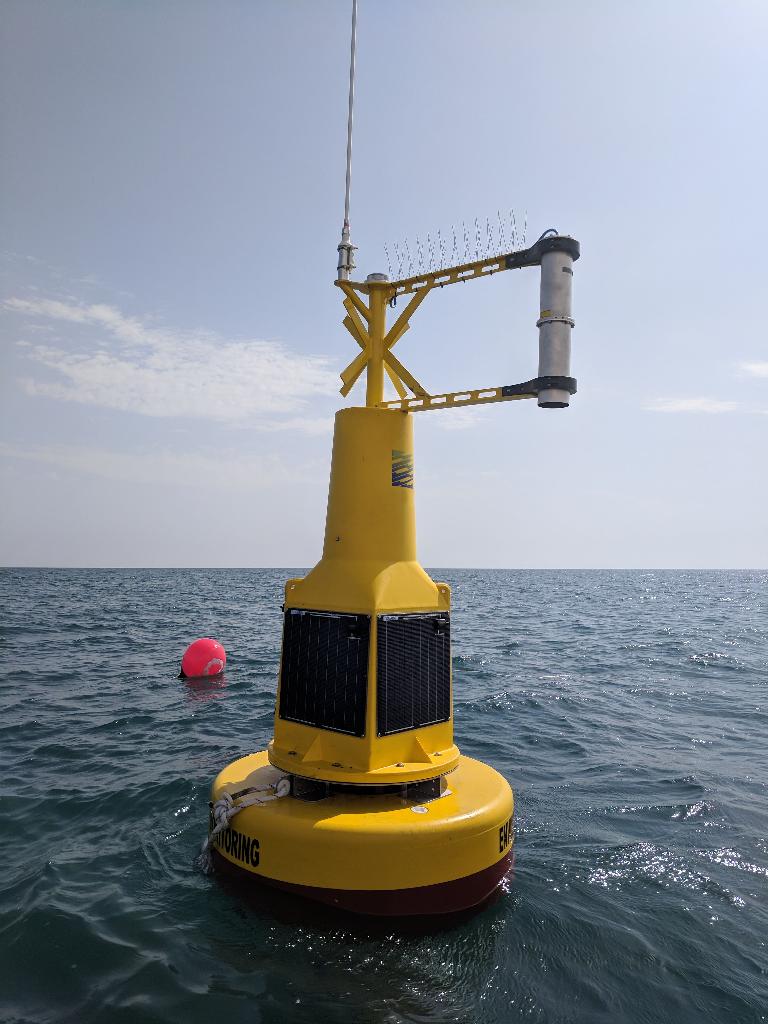

In a busy shipping area, ROW sensors mounted on solar-powered buoys preemptively detect oil before it reaches intake systems. This proactive solution shields both water intake and marine ecosystems.

TOTAL Refinery, Antwerp

Using ATEX-rated ROW detectors, this facility monitors wastewater sump pits, ensuring discharged water remains compliant. The instant alerts allow operators to respond quickly and prevent environmental incidents.

Technical Highlights

| Feature | Specifications |

|---|---|

| Detection Sensitivity | ≤ 1 µm oil film |

| Detection Range | Up to 10 m |

| Power Consumption | < 2 W (solar-compatible) |

| Housing Options | Aluminium, 316L stainless steel, ATEX EXD |

| Telemetry | Relay, 4–20 mA, RS-485; SCADA/LMS compatible |

Take Action: Secure Your Facility Today

Protecting water treatment infrastructure from oil contamination is more important than ever. With ROW, you get a proven, cost-effective monitoring solution that ensures compliance, safeguards infrastructure, and upholds environmental standards.

Want to discuss how ROW can integrate into your water treatment system? Visit the ROW product page or Contact us today!

Search

Recent Posts

- Hydroelectric Safety Reinvented: Continuous Oil Monitoring for Turbine Protection

- Continuous Water Monitoring: Refineries and Oil Terminals

- Extreme Stress Test: How the LDI Sensor Survived a Ship Impact and a Month in the Frozen Sea

- LDI Demonstrates Autonomous Oil Spill Detection in Tallinn

- How ROW Supports the EU’s DIGIMARIS Marine Spill Response Project