Why ATEX/IECEx Zone‑1 Compliance Sets ROW Apart

Ensuring safe operations in hazardous areas is critical for industries handling flammable liquids or gases. LDI’s Remote Optical Watcher (ROW) stands out with its ATEX and IECEx Zone‑1 certified model—offering unmatched performance in explosive environments. This certification not only ensures regulatory compliance but also delivers peace of mind for operators working in high-risk contexts.

Understanding ATEX & IECEx Zone‑1 Certification

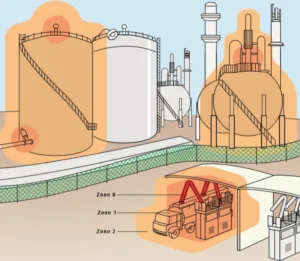

ATEX Zone 1 refers to environments where explosive atmospheres from flammable gases or vapors are likely to occur during regular operations. IECEx complements this by offering a globally recognized scheme for equipment certified for such conditions.

Achieving Zone‑1 compliance involves rigorous design and testing to ensure that under fault conditions, the equipment cannot ignite an explosive atmosphere—making it essential in sectors like oil & gas, petrochemicals, and fuel handling.

ROW ATEX EXD: Certified for Compliance and Safety

ROW’s ATEX EXD model (O‑2301E/O‑4501E) comes in a flameproof, 316L stainless steel casing, certified by third parties such as DNV. It meets ATEX/IECEx Zone‑1 standards while delivering:

-

IP68 water and dust protection

-

Detection of oil films as thin as 1 µm

-

Detection range up to 8 m

-

Robust functionality in –25 °C to +60 °C environments

This model is ideal for monitoring in hazardous settings like fuel depots, petrochemical plants, and marine terminals.

Compliance Benefits: Why Certification Matters

1. Enhanced Safety

Zone‑1 certification prevents explosion hazards even under fault conditions, significantly reducing risk to personnel and equipment .

2. Regulatory Trust and Market Access

ATEX and IECEx are recognized worldwide, easing international deployment and avoiding redundant testing and paperwork

3. Operational Reliability

Quality-certified equipment ensures consistency, reduces downtime, and avoids the hidden costs of unplanned failures or compliance breaches.

4. Insurance & Cost Advantages

Regulators and insurers favor certified systems, leading to improved coverage terms and lower insurance costs over time.

Technical Overview

| Feature | ROW ATEX EXD (Zone‑1) |

|---|---|

| Enclosure | Flameproof 316L stainless steel, IP68 |

| Certification | ATEX II 2 G Ex d IIB, IECEx Gb, NEC/CSAO Class 1 |

| Sensitivity | ≤ 1 µm oil film |

| Detection Range | Up to 8 m |

| Temperature Range | –25 °C to +60 °C |

| Power Consumption | <2 W, suitable for solar/battery setups |

| Telemetry Outputs | Relay, 4‑20 mA, RS‑485, Modbus, wireless options |

| LED Lifetime | 5 years |

Integrated Solutions for All Environments

ROW comes in three enclosure options—Aluminium, 316L Stainless Steel, and ATEX EXD—allowing you to use the same high-performance detection technology across ordinary, corrosive, and explosive settings. Integration with SCADA or telemetry networks supports centralized monitoring and rapid response to contamination events.

Secure Protection in Hazardous Zones

LDI’s Zone‑1 certified ROW ATEX EXD is indispensable for operations in explosive atmospheres—delivering safety, compliance, and peace of mind. Whether you’re operating in fuel terminals, refineries, marine ports, or chemical plants, ROW ensures reliable, real-time detection without compromising safety.

Discover the full range of ROW models, visit the ROW product page or Contact us today!

Search

Recent Posts

- Hydroelectric Safety Reinvented: Continuous Oil Monitoring for Turbine Protection

- Continuous Water Monitoring: Refineries and Oil Terminals

- Extreme Stress Test: How the LDI Sensor Survived a Ship Impact and a Month in the Frozen Sea

- LDI Demonstrates Autonomous Oil Spill Detection in Tallinn

- How ROW Supports the EU’s DIGIMARIS Marine Spill Response Project