How to Optimize Your ROW Sensor for Peak Performance

Oil spills present serious risks to the environment, infrastructure, and operational safety. Early detection is critical to avoid contamination, reduce cleanup costs, and remain compliant with strict environmental regulations.

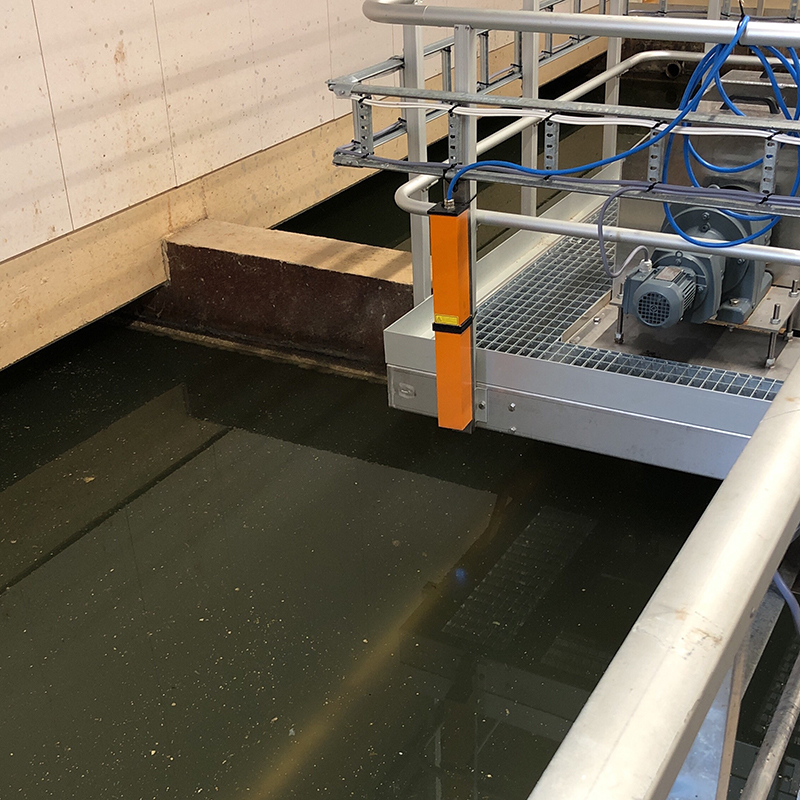

LDI’s ROW Oil Spill Detector is designed to deliver real-time, non-contact monitoring of hydrocarbons on water surfaces. But like any precision instrument, achieving peak performance requires correct installation and configuration. In this article, we’ll walk through the best practices to ensure your ROW sensor delivers maximum sensitivity and reliability—whether installed at ports, refineries, desalination facilities, or water treatment plants.

Mount at the Right Height

The effectiveness of ROW begins with its placement. To take advantage of its best-in-class sensitivity (detecting films as thin as 1 µm) and range (up to 10 m, with long-range models available up to 25 m), the sensor must have a clear, unobstructed view of the water surface.

If installed too low or with obstacles in the line of sight, detection accuracy can be compromised. By mounting the ROW at the optimal height, operators ensure reliable, real-time monitoring of stormwater outlets, tank bunds, intake channels, or offshore platforms.

This installation step is especially important in:

-

Desalination plants, where oil contamination can damage osmosis membranes.

-

Airports, where stormwater runoff often contains jet fuel residues.

-

Industrial facilities, where bund overflows can lead to costly fines.

Connect It Correctly

The ROW was designed with integration flexibility in mind. Depending on your facility’s infrastructure, the sensor can be connected through:

-

RS-485 (Modbus) for industrial communication networks.

-

4–20 mA outputs for seamless integration into PLC and SCADA systems.

-

Relay outputs for simple alarms or shutdown triggers.

-

Wireless telemetry for remote installations or off-grid monitoring.

This ensures that the ROW fits into a wide range of monitoring setups, from large-scale refineries to remote desalination plants where wired infrastructure is limited.

Simple, One-Minute Configuration

Unlike many complex monitoring systems, the ROW requires minimal setup. Configuration takes around one minute, after which the sensor is fully operational.

This quick setup means that facilities can deploy ROW detectors rapidly during emergency scenarios, or scale them across multiple monitoring points without significant downtime.

Continuous, Autonomous Monitoring

Once installed and connected, the ROW begins working autonomously, providing continuous monitoring day and night. Equipped with:

-

IP68-certified enclosures, ensuring resilience in harsh weather and marine environments.

-

Low power consumption (<2 W), making it suitable for off-grid and solar-powered deployments.

-

Advanced software algorithms, reducing false alarms while maintaining industry-leading sensitivity.

The ROW ensures that operators are alerted instantly—via SMS, email, or SCADA integration—when oil is detected. This real-time response gives teams the opportunity to contain spills before they escalate into large-scale incidents.

Why Optimization Matters

A ROW sensor is already one of the most advanced oil spill detection tools available, but optimizing its installation and configuration maximizes its value. Properly deployed sensors help facilities:

-

Protect freshwater systems from hydrocarbon contamination.

-

Safeguard industrial operations by preventing costly shutdowns.

-

Meet environmental compliance with regulators and stakeholders.

-

Demonstrate ESG responsibility, improving reputation and trust.

By ensuring correct installation, reliable connectivity, and proper setup, operators unlock the full capabilities of ROW technology—leading to cleaner water, safer operations, and peace of mind.

To explore the different ROW models and their applications, visit our ROW Oil Spill Detector product page.

You can also read real-world deployments in our ROW case studies across airports, refineries, ports, and water treatment facilities.

Search

Recent Posts

- Hydroelectric Safety Reinvented: Continuous Oil Monitoring for Turbine Protection

- Continuous Water Monitoring: Refineries and Oil Terminals

- Extreme Stress Test: How the LDI Sensor Survived a Ship Impact and a Month in the Frozen Sea

- LDI Demonstrates Autonomous Oil Spill Detection in Tallinn

- How ROW Supports the EU’s DIGIMARIS Marine Spill Response Project