How to Choose the Right Oil Detection System for Your Industry

Oil spills, even small ones, can cause major disruptions across industries—from costly downtime and regulatory fines to long-term environmental damage. Choosing the right oil detection system is essential to protecting both operations and ecosystems. But with so many environments and risk profiles, how do you decide which system best fits your needs?

This guide outlines the key factors to consider and shows how ROW (Remote Optical Watcher) technology provides tailored solutions for diverse industries.

Understanding Your Industry’s Needs

The first step in selecting an oil detection system is recognizing the specific risks in your sector.

-

Ports & Terminals – High vessel traffic and fuel transfers make early detection crucial.

-

Airports – Runways, aprons, and fuel tank farms require continuous monitoring for jet fuel spills.

-

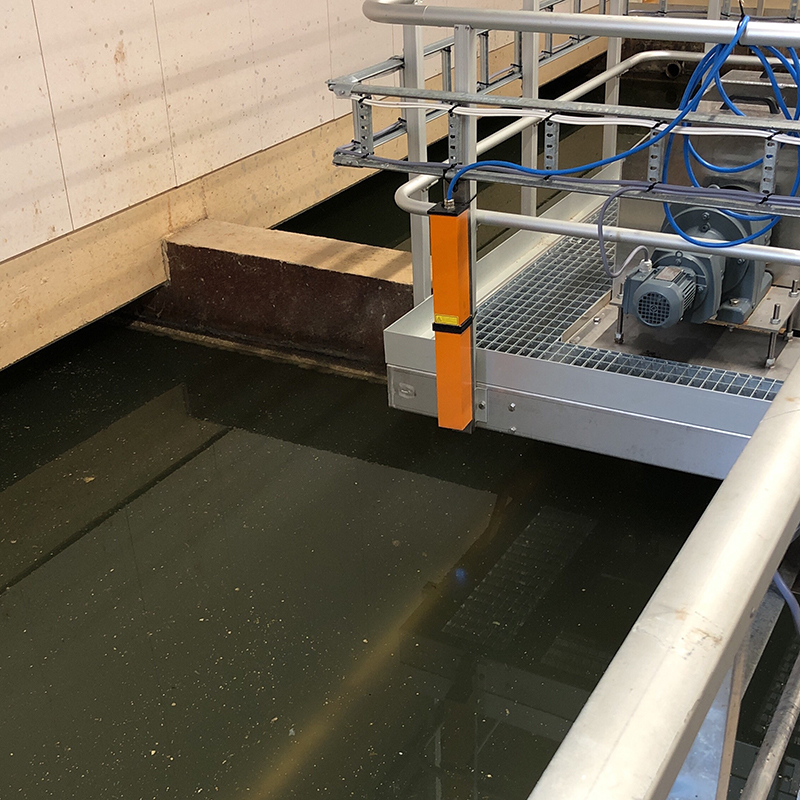

Water Treatment Facilities – Oil contamination can overwhelm processes and compromise drinking water.

-

Desalination Plants – Sensitive membranes are at risk from even minor hydrocarbon pollution.

-

Refineries & Industrial Sites – Complex operations with large volumes of oil need instant alerts to prevent costly shutdowns.

Each of these environments requires a solution that can detect oil quickly, reliably, and in real time.

Key Factors to Consider

When choosing an oil detection system, focus on these critical elements:

-

Detection Sensitivity – Can it detect films as thin as 1 μm before a small leak becomes a big problem?

-

Range – Do you need short-range monitoring (e.g., bunds, channels) or long-range coverage (e.g., offshore installations)?

-

Enclosure Material – Aluminium for lightweight applications, 316L Stainless Steel for corrosive or marine environments, or ATEX/IECEx Zone-1 certified enclosures for hazardous areas.

-

Integration – Compatibility with telemetry, SCADA systems, or standalone operation.

-

Reliability – Weatherproof design (IP68) and continuous, low-power operation are critical for harsh or remote sites.

Why ROW Stands Out

The ROW Oil Spill Detector is engineered to provide:

-

Real-time, non-contact detection using UV fluorescence.

-

Unmatched flexibility, with models tailored to industry-specific environments.

-

Seamless integration via RS-485 (Modbus), 4–20 mA, or relay outputs.

-

Field-proven success across airports, ports, water treatment plants, and more.

Whether it’s safeguarding freshwater systems, protecting coastal infrastructure, or ensuring compliance in high-risk industrial zones, ROW offers solutions that match your environment.

Making the Right Choice

Selecting the right oil detection system isn’t about one-size-fits-all—it’s about choosing the right tool for the job. By evaluating your industry’s risks, operating conditions, and compliance needs, you can ensure effective protection for your operations and the environment.

Explore the ROW product page to compare models and find the best solution for your facility.

Search

Recent Posts

- Hydroelectric Safety Reinvented: Continuous Oil Monitoring for Turbine Protection

- Continuous Water Monitoring: Refineries and Oil Terminals

- Extreme Stress Test: How the LDI Sensor Survived a Ship Impact and a Month in the Frozen Sea

- LDI Demonstrates Autonomous Oil Spill Detection in Tallinn

- How ROW Supports the EU’s DIGIMARIS Marine Spill Response Project